What Are Popular Sizes of Aluminum Tread Plates

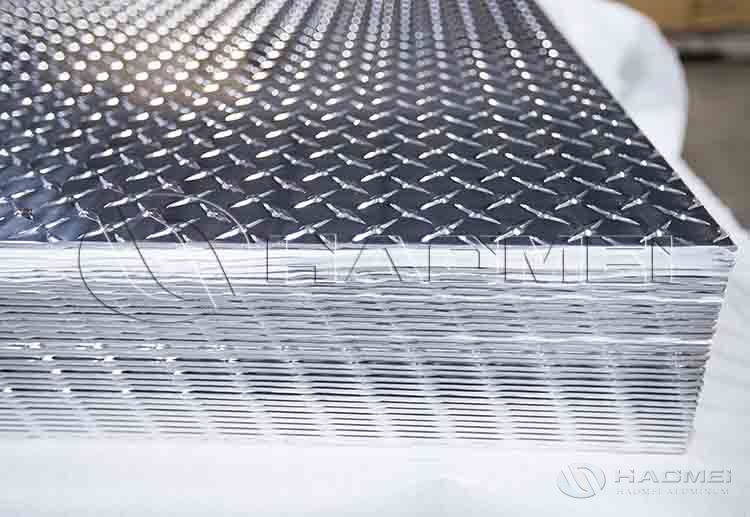

In the fields of architectural decoration, industrial manufacturing, transportation equipment, etc., aluminum tread plates have become a popular material due to their unique anti-slip properties, beautiful appearance and excellent corrosion resistance. When we buy patterned aluminum plates, we always find that 4x8 feet (about 1.22 meters x 2.44 meters) is the most common specification. In addition, 3x6 feet, 5x10 feet and other sizes are also popular.

1. Common sizes of aluminum diamond plates

The mainstream sizes of patterned aluminum plates on the market are divided in feet, mainly including:

Diamond plate 4 x 8 sheets (1220mm×2440mm): occupies more than 70% of the market shipments, suitable for most conventional scenarios.

3x6 feet (915mm×1830mm): the first choice for small projects or sample orders, convenient for transportation and local construction.

5x10 feet (1525mm×3050mm): commonly used for large-scale project customization, which can reduce splicing and improve integrity.

Other specifications: such as 1x2 meters, 1.5x3 meters and other non-standard sizes, which need to be customized according to specific needs.

2. Three core reasons why 4x8 feet has become mainstream

Matching upstream aluminum rolling process

The width of the original plate formed after the aluminum ingot is smelted and cast is usually in the range of 1.2-1.3 meters, which is determined by the roller width of the hot rolling mill. The original plate is cut into a width of 1220mm (4 feet) longitudinally and extended to 2440mm (8 feet) horizontally, which just meets the optimal cutting ratio for aluminum coil flattening:

The utilization rate of a single sheet can reach more than 98%, with almost no waste generated.

Matching the mold specifications of mainstream rolling mills, reducing the cost of changeover and debugging

Facilitating intelligent slitting of automated production lines and improving production efficiency

Meeting the needs of efficient logistics and warehousing

In the logistics and transportation link, 4x8-foot aluminum sheet have unique adaptability:

Road transportation: The width of the domestic standard truck cargo box is 2.3-2.4 meters, and 2 panels can be placed side by side in a single row (total width 2.44x2=4.88 meters), and 10-15 layers can be stacked in height, and the single vehicle loading capacity is stable at 300-500 sheets

Sea container: The inner diameter of the 20-foot cabinet is 5.9x2.35x2.39 meters, and 25 rows of 2440mm panels can be placed horizontally, and 4 rows of 1220mm can be placed vertically, with a single cabinet capacity of more than 1,000 sheets.

Warehouse management: The standard shelf layer height is 3 meters, 2440mm boards can be stored upright, and the 1220mm width is convenient for manual handling.

Adapt to the needs of terminal application scenarios

In actual engineering applications, the 4x8-foot specification shows strong versatility:

Architectural decoration: The standard ceiling module size is 600x600mm, 2440mm length can cut 4 standard boards (with 40mm edge material), 1220mm width can cut 2 boards with 20mm left, and the material utilization rate is more than 96%

Industrial platform: The common steel platform spacing is 1.2 meters, and the 2.44-meter length can span two spans of the support structure, reducing the amount of brackets; when the anti-slip pattern faces up, a single sheet can cover 3 square meters of the working surface

Transportation field: The standard size of the container floor is 1220x2440mm, which directly matches the patterned aluminum plate specifications; when cutting the automotive interior panel, it can fully cover the maximum size of the doors, ceilings and other parts.

3. How to choose the right size?

Measurement of usage: Calculate the number of panels according to the construction area, and give priority to mainstream sizes to reduce losses.

Consideration of transportation: For remote areas or small batch purchases, 3x6 feet is more suitable to avoid transportation overload.

Construction conditions: For high-altitude operations or narrow spaces, lightweight and small sizes are safer and easier to operate.

Design requirements: Pursue seamless splicing effects, and large-size panels can be customized (processing cycle needs to be confirmed).

As one of the big aluminum sheet manufacturers, Haomei Aluminum can provide different sizes of aluminum tread plates for you.

Original source: https://www.hm-alu.com/a/what-are-popular-sizes-of-aluminum-tread-plates.html