Decorative Aluminum Sheet and Sublimation Aluminum Sheet

The color coated aluminum sheet is also widely used in the field of interior decoration, such as ceilings, partitions, wall panels, etc. The application of decorative aluminum sheetcan enhance the overall beauty and grade of the indoor environment. Its flat and smooth surface is easy to clean and maintain, and it also has good sound insulation and heat insulation properties.

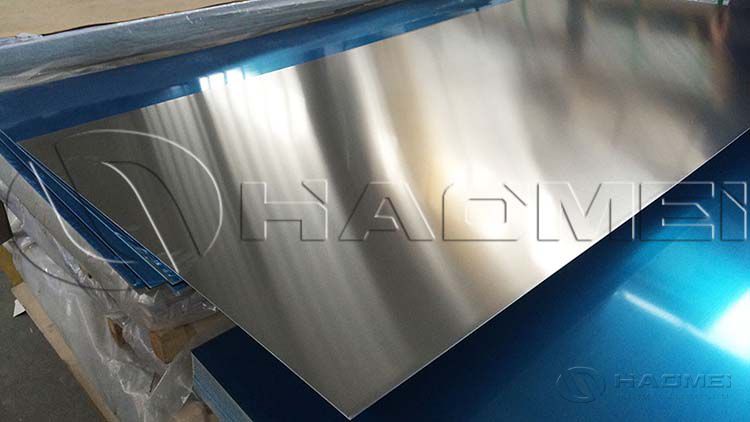

The decorative aluminum sheets use high-quality 1060, 3003, 3004 and other aluminum plates as substrates. Commonly used topcoats include polyester (PE), HDP (high durability polyester), silicon-modified polyester (SMP) and PVDF (polyvinylidene fluoride). Primers and backcoats include epoxy (EP), polyester (PE), polyurethane (PU), etc.

The color of the color coating can be customized according to the RAL color card or other standard color card numbers, or it can be processed according to the sample color. Therefore, color-coated aluminum coils require a certain processing cycle before delivery. Users should consider the processing time when ordering, and try to order in advance to avoid processing time.

Although the familiarity of dye sublimation printing technology is not as good as the two basic printing technologies of inkjet and laser in the office field. However, it has unique advantages in photo output, fabric and cup transfer, especially in the effect of photo printing, with extremely high image resolution, natural color transition, and easy preservation. It has become the preferred printing method for many color digital photo printing industries. Aluminum sublimation blanks is used for this purpose.

The sublimation aluminum sheet also choose color coated aluminum sheet. Substrate pretreatment technology is produced along with the production of coating technology. It serves coating technology and lays the foundation for the preparation of excellent coatings. All substrates of pre-coated aluminum coils will have some grease and lubricants on the surface during the production process. Of course, other substances may also adhere to them during transportation. If these grease and adhesions are not removed, it will affect the coating and use of the aluminum coils. In addition, the surface of the clean substrate needs to be chemically treated to generate a stable conversion film, thereby improving the corrosion resistance of the substrate and the adhesion of the coating.

The coating process is a more critical step in the production of colored aluminum coils, which directly affects the final coating quality and the durability of the product. Therefore, the coating process is very strict. With the continuous improvement of coating equipment and the development and utilization of new coatings, the production of coated aluminum coils has become more mature and the processing fee has also decreased. Coated aluminum coils have therefore achieved rapid development.

Original source: https://www.hm-alu.com/a/decorative-aluminum-sheet-and-sublimation-aluminum-sheet.html

Tags:color coated aluminum sheet

Prev: 6061 Aluminium Sheet 8x4

Next: 3003 1060 Aluminum Discs