Aluminum Reflector Sheet for Floodlight

In outdoor lighting, stage lighting and other scenes, floodlights occupy an important position with their large-area lighting effects. In the construction of floodlights, the aluminum light reflector sheet occupies an important position, which directly affects the lighting efficiency and service life of floodlights. So, what are the specific requirements of floodlights for mirror aluminum plates?

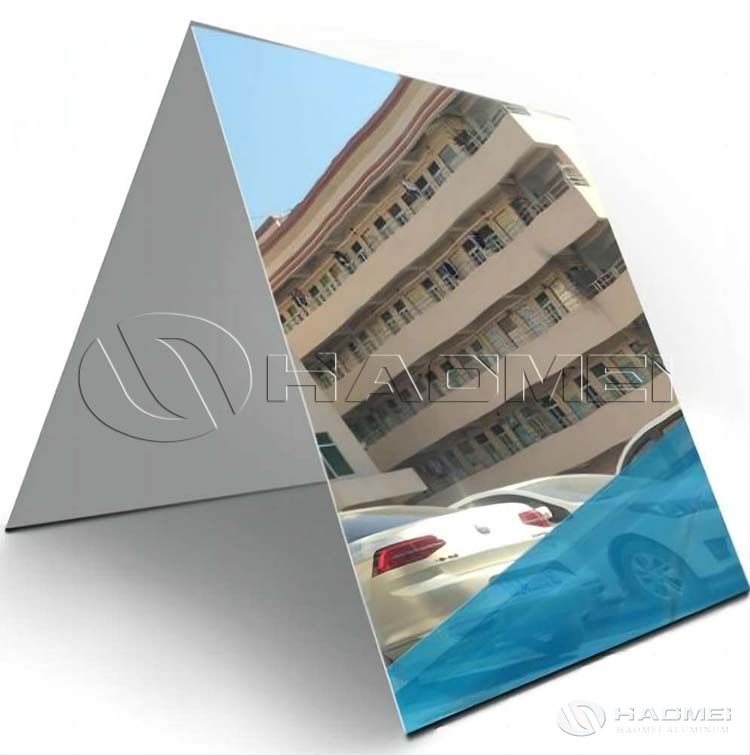

Extremely high reflectivity is the core requirement of floodlights for mirror polished aluminum sheets. The working principle of floodlights is to emit light through the light source, and then reflect it through the mirror aluminum sheet, so as to achieve large-area lighting.

If the reflectivity of the mirror aluminum plate is not enough, a large amount of light will be absorbed or scattered, resulting in a significant reduction in the lighting effect. The reflectivity of high-quality reflective aluminum plates can usually reach more than 85%, and some high-end products can even exceed 90%, so that the energy of the light source can be converted into effective lighting to the maximum extent.

Good weather resistance is also essential. Floodlights are mostly used outdoors and need to withstand the test of various harsh environments such as wind, sun, and rain. If the mirror aluminum plate has poor weather resistance, it is easy to oxidize, corrode, discolor, and other problems during long-term use, which will affect the reflective effect.

Therefore, the surface of the mirror aluminum plate is usually specially treated, such as coating a protective film or anodizing, to enhance its corrosion resistance and UV resistance, and ensure stable performance under various climatic conditions.

High flatness is also critical. The surface flatness of the polished aluminum sheet will directly affect the reflection direction of the light. If the surface is not flat, the light will be scattered in a disorderly manner when reflected, and it will not be able to form a concentrated and uniform lighting area. This requires the mirror aluminum plate to strictly control the flatness during the production process to avoid defects such as bumps and wrinkles, and ensure that the light can be evenly reflected at the designed angle.

In addition, the appropriate thickness and strength also need to be considered. The aluminum mirror sheet needs to have a certain thickness and strength to ensure that it is not easy to deform during installation and use.

If the aluminum sheets for sale are too thin or insufficiently strong, they are easy to bend when subjected to external force, thereby changing the reflection angle and affecting the lighting effect. At the same time, the appropriate thickness can also enhance the heat dissipation performance of the aluminum plate, because the floodlight will generate a certain amount of heat when working, and good heat dissipation helps to extend the service life of the light source and the aluminum plate.

The last but not the least, excellent processing performance is also important. Floodlights come in a variety of shapes. In order to meet different design requirements, the reflective aluminum mirror sheet needs to be able to undergo a variety of processing operations such as cutting, bending, and stamping. If the processing performance is poor, it will be difficult to produce parts that meet the structural requirements of floodlights, increasing production difficulty and cost. Homei Alumnium provide such aluminum mirror sheet. Welcome to leave message below to tell us your need.

Original source: https://www.hm-alu.com/a/aluminum-reflector-sheet-for-floodlight.html